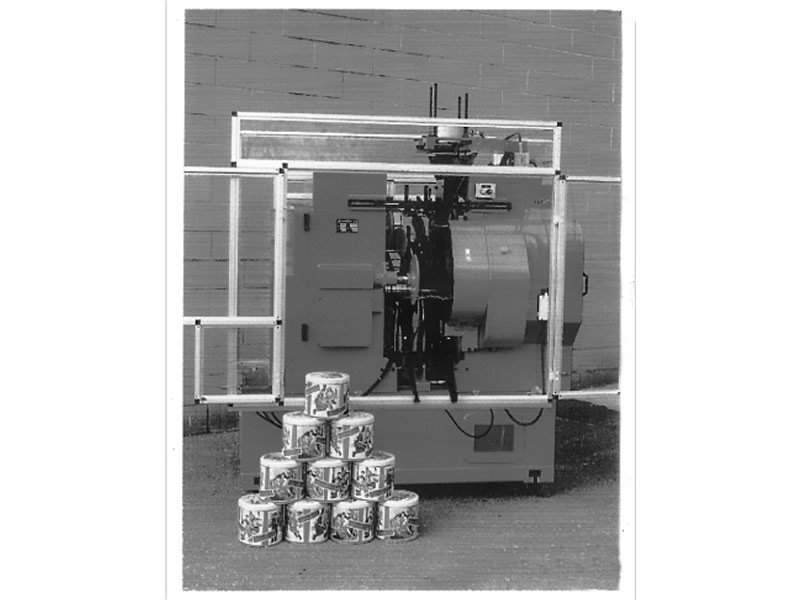

| Double die flanging and automatic bottom seamer

GENERAL CHARACTERISTICS

This machine, based on the most recent and modern execution of the STAV175 model, is used for the automatic production of cylindrical cans, with the following operations:

– Single or bilateral die necking with special additional station, to obtain stackable boxes

– Flanging on both sides or flanging on one side and internal or external curl at the opposite end, by means of dies, for the application of a pressure lid

– Seaming of the bottom or lid or ring with aluminum seal and pressure lid.

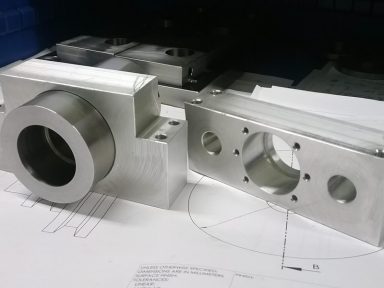

The use of the dies system allows an exact calibration of the can bodies, particularly recommended for the subsequent seaming operation which takes place when the can is stationary by means of a seaming head with four rollers (two for the first and two for the second operation), which guarantees an absolutely secured closure. The change in diameter takes about an hour of work while the transition to a different can height is done with a few adjustments in a few minutes. The machine is equipped with a 4kW three-phase electric motor and an electronic speed variator mounted inside the separate control panel.

TECHNICAL DATA

Max. Speed: 60 cans/min

Diameters: from 99 to 260 mm

In special execution: from 73 to 99 mm

Heights: from 66 to 400 mm

Max sheet thickness: 0,4 mm

Power: 4 Kw

Noise level: 85 dB

Weight: 3120 Kg

Max dimensions: 150 x 220 x 230 cm

“It’s easier to love a brand when the love is reciprocated.”